Borfit Reinforced Thermoplastic Pipe

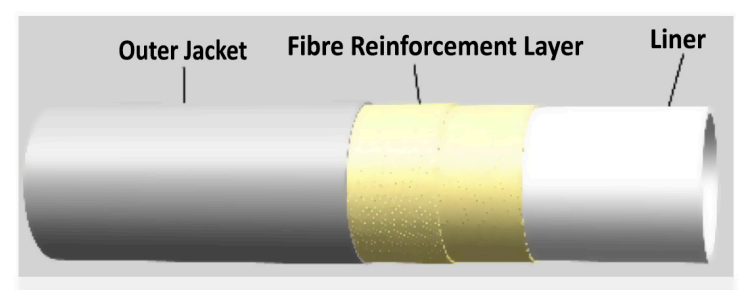

Reinforced Thermoplastic Pipe (RTP) is typically three-layer structure consisting of a liner, a reinforcement

layer, and an outer jacket.

Liner: It is the medium transmission layer of RTP, with excellent corrosion resistance, for which high polymer materials such as HDPE, PE-RT, PEX, PA, PVDF, UHMW-PE and POE co-extruded wear-resistant layer can be selected according to the working conditions.

Reinforcement Layer: It is the pressure bearing layer of RTP, which is reinforced and wound with materials such as polyester fibre filament, polyester fibre prepreg tape, aramid fibre filament, aramid fibre prepreg tape, glass fibre prepreg tape or steel cord tape.

Outer Jacket: It protects the reinforcement layer from external damage and has certain wear and UV resistance, which is generally made of high polymer materials such as HDPE and PE-RT. Borfit RTP Pipes are as stronger as steel pipes but they are more durable as opposed to them. Corrosion, the biggest trouble for metal pipes, is no longer a problem.

Moreover, necessity of using steel pipes where there is a need of high-pressure resistance is overcomed by Borfit technology.

Borfit RTP Pipes present pressure resistance up to 200 bars even up to 315 mm diameter. Yet for bigger diameters, RTP Pipes still provides better solutions. Combining the advantages of plastic pipes for flexibility, chemical resistance, corrosion resistance and easy application features with high pressure and high temperature resistance by Borfit technology, Borfit RTP Pipes are the best solution for special projects. Designed as 3-layered, Borfit RTP Pipes can be produced from PN16 to PN320. Thanks to its inner layer of continuous reinforced glass fibre.

Borfit RTP Pipes also decreases the project costs and shortens the project durations by lowering the time needed production and assembling.

Product Features and Application Fields

Borfit Reinforced Thermoplastic Pipe (RTP) is a type of high-pressure plastic composite pipe with good flexibility, corrosion resistance, high pressure resistance, wear resistance and impact resistance, which is in light weight, coil able, requires few joints, and of fast installation. It is corrosion resistant compared to steel pipes and pressure resistant compared to plastic pipes.

It can be applied in single well oil and gas transportation, mixed oil and gas transportation, high-pressure water injection, scattered gas recovery, sewage transportation, and underwater shallow sea gathering and transportation in the process of oil and gas exploitation, as well as salt chemical brine transportation, slurry transportation, urban heat supply, hot spring water transportation and other fields.

Steel pipes used in streaming have high pressure strength whereas they have low corrosion strength. Plastic pipes, on the other hand, have high corrosion strength and limited pressure strength. High corrosion strength and high-pressure strength are both necessary for pipes in high pressure drinking and usage water, geothermal water carriage lines, hydro electrical power plants, petrol transmission lines, industrial facilities etc.

Borfit RTP Pipes with their composite structure provide pressure strength with their constant fibres in the middle layer which is much more resistant than the steel. The polymer raw material over and under the fibre layer provides high corrosion strength.

Borfit RTP Pipes’ design concept belongs to the composite product segment which has improved fast in recent years and stood out especially in aviation, automotive, space, construction etc. Different materials have strong and weak sides. With composite design, it is possible to bring together the strong points of different materials. In RTP Pipes, continuous fibres’ high tensile strengths are combined with high corrosion strength. The combination method provides a structure in which the constant fibre layer and polymer layer can work together due to advanced technology.

RTP Product Classification

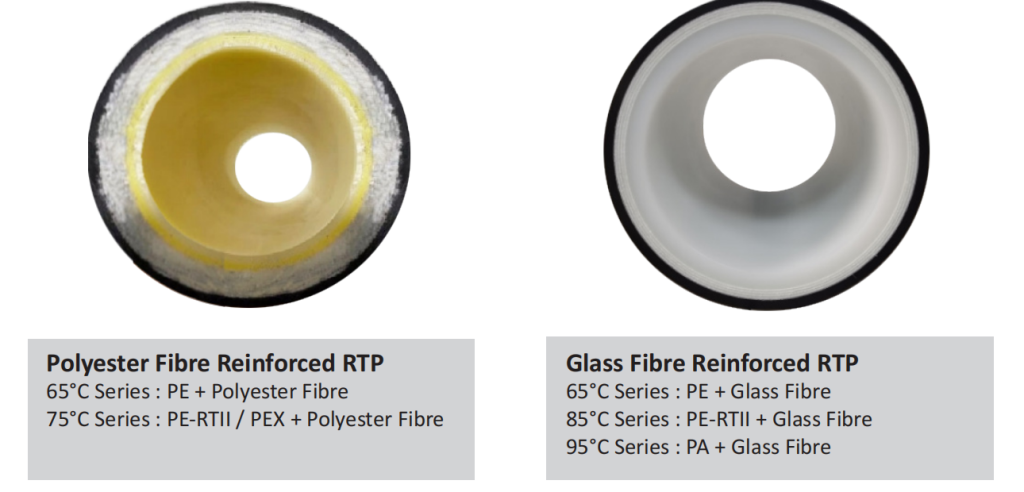

Classification According to The Reinforcement Materials

RTPs can be classified into four categories according to the reinforcement layer materials :