MODEL"SC" Single Chamber Orifice Fitting

The Canalta Single Chamber Orifice Fitting is designed and constructed to allow for ease of orifice plate replacement or inspection after depressurization.

The Canalta SC Orifice Fitting is a high quality, high accuracy orifice fitting manufactured in a wide selection of sizes and materials. These units are built to meet or exceed ASME and ANSI specifications as well as to comply with the requirements of the latest editions of AGA-3, ISO-5167and API-14.3. The fittings are available to meet the NACE MR-0175 specification. Stainless Steel internals are also available to meet extreme corrosive applications.

FUNCTIONING AND STRUCTURE

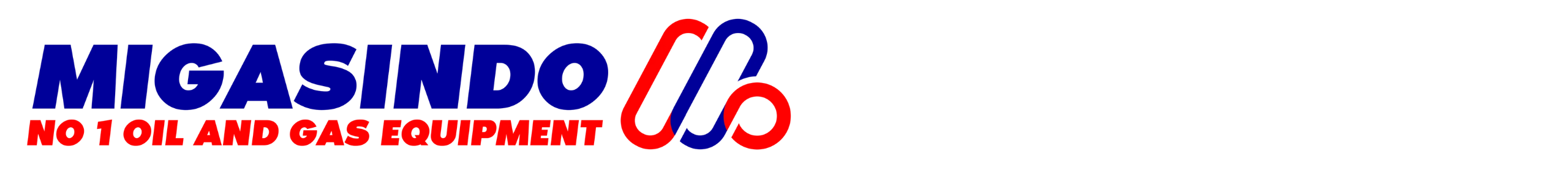

1. Type “K” Standard 2000 Edition Seal Assembly

This is the standard seal assembly supplied with all orifice fittings from sizes 2” through 8”. This unit is used with a 0.562” seal gap for fitting sizes 2” thru 6” and with a 0.688” seal gap for 8” fittings. The single downstream seal function offers superior sealing capability while reducing seal damage during insertion. Plate Seal bypass tested down to 1” water column. It is comprised of an elastomer seal and one stainless steel retainer ring. Exacting and repeatable concentricity is maintained with the metal-to-metal contact throughout the entire circumference of the orifice plate to the plate carrier mechanism.

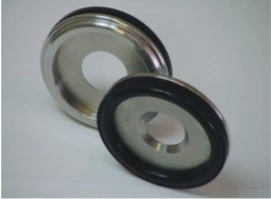

2. Dual Ring Orifice Plate Seal Assembly

Canalta Dual Ring Orifice Place Seal Assembly offers you (The Customer) an alternative sealing device for those specific or unorthodox situations. This assembly is primarily used to upgrade the .688” seal gap (1985 Edition) orifice fitting bodies to comply with the latest editions of AGA-3 and ISO-5167 but is also available for 0.562” gap fittings (2000 Edition) per customer request. The seal assembly simply mounts into place in the existing plate carrier. It is comprised of a stainless steel plate holder, retainer ring and standard sized O-Ring seals which are available in a variety of compositions. A positive seal is established with the orifice plate and the seal surfaces of the orifice fitting body utilizing the “inner and outer O-Ring” design. Plate seal bypass tested down to 1” water column. When ordering the Dual Ring Orifice Plate Seal Assembly please specify 0.688” seal gap (1985 Edition) or 0.562” plate seal gap (1991 / 2000 Edition).

3. Teflon Snap Seal

The Teflon Snap Seal Provides Positive Plate Sealing in the harshest of process environments. The two piece design snaps over the orifice plate without the use of metal clips or retainers. A specially designed recess absorbs the insertion pressures minimizing permanent compression and distortion. The raised section adjacent to the recess creates a positive seal against the orifice plate preventing bypass leakage. These two unique design features enhance seal performance while extending the life expectancy of the seal assembly.