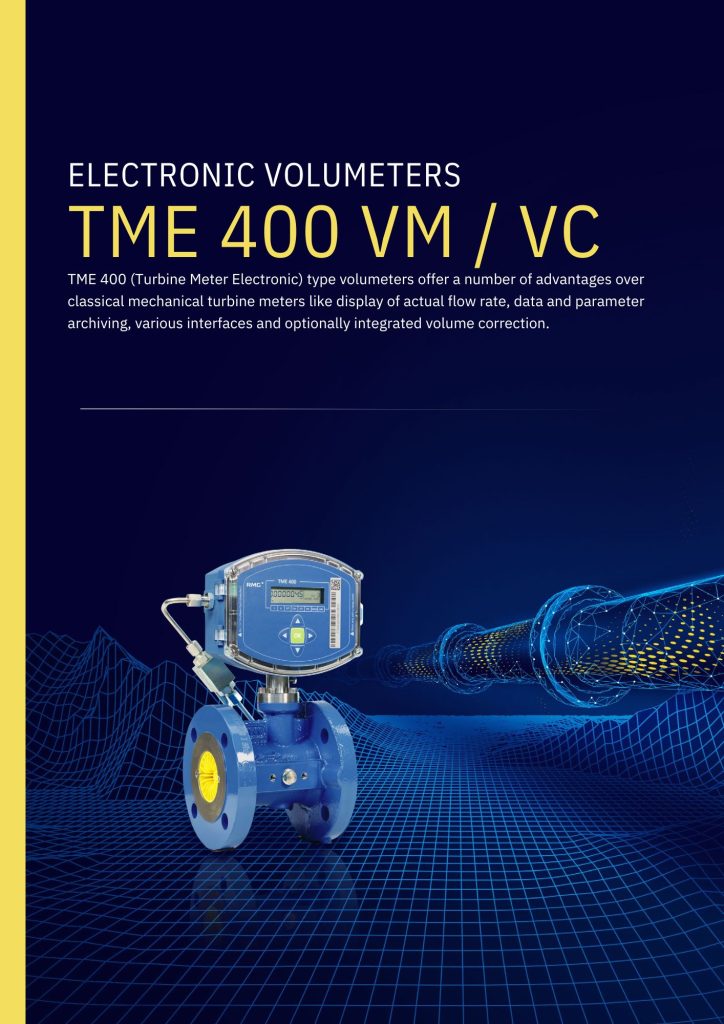

ELECTRONIC VOLUMETERS TME400 VM/VC

TME 400 (Turbine Meter Electronic) type volumeters offer a number of advantages over

classical mechanical turbine meters like display of actual flow rate, data and parameter

archiving, various interfaces and optionally integrated volume correction.

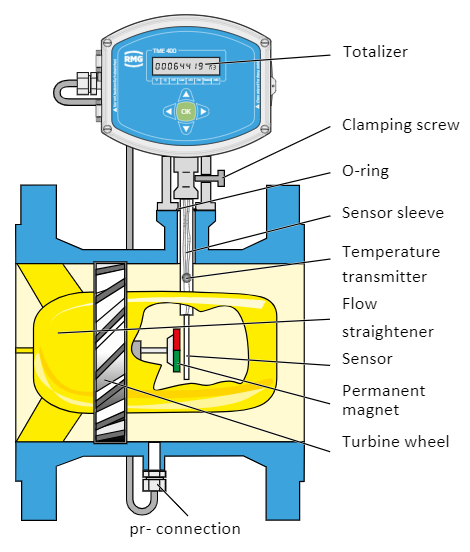

METHOD OF OPERATION, CONSTRUCTION

Introduction

The new type TME 400 volumeters are turbines designed for secondary metering (non custody transfer operation) with purely electronical totalizers. In contrast to mechanical turbine meters, in the TME 400 the volume flow is converted in the mechanical meter body to electrical impulses, which are transmitted to the electronical meter head where they are processed. In this way, the TME 400 can not only display and save the totalizer reading, but also, for example, the actual flow rate. In addition, several totalizers can be realized and the meter can transmit its measured values as well as additional signals directly via various interfaces (pulses, analog, digital). Furthermore, the version TME 400-VC offers a fullyfledged volume corrector integrated in the meter head, including pressure and temperature measurement.

It calculates the standard volume besides operating flow rate

and operating volume. An external volume corrector is no longer

needed. For all TME 400 versions, a long-lasting backup battery

ensures continued reliable operation even in the case of a

complete power failure.

TME 400-VM

The TME 400-VM (Volume Meter) is the basic version of the TME 400 family. As the abbreviation VM indicates, it is a so-called volumeter, i.e. a pure operating volume meter for non-custody transfer applications.

Features

- Electronic totalizers Main totalizer, additional start-stop or resettable totalizer for low flow (or slow down) cut-off by external signal.

- Low-torque metering system with long-term stability Turbine design with a minimum of moving parts.

- Battery or mains operation Autonomous operation with lithium cell for 6+ years or external power supply and backup battery to protect against power failures.

- Explosion protection The TME 400 is intrinsically safe and can be used in zones 1 and 2.

- Outputs Pulse outputs HF and LF (variable), alarm output, current output (4-20 mA, optional).

- Flow display

- Digital interface serial RS 485 interface for Modbus connection.

- Storage of maximum value (Qm)

- Archive Integrated fail-safe parameter, event and measured value archive.

- RMGViewTME Provided software for convenient parameterization and management of device and stored data.

TME 400-VC

The TME 400-VC (Volume Corrector) combines all features of the TME 400-VM with the benefits of a fully integrated non-custody transfer PTZ volume corrector. Pressure and temperature measurement are integrated directly into the meter.

Additional Features (VC)

- Volume corrector Integrated fully-fledged compact volume corrector including digital pressure and temperature measurement.

- Calculation of the K coefficient according to SGERG88, AGA8 GROSS M1 and M2 as well as AGA NX19.

- Display Operating volume, standard volume, current and maximum flow can be displayed in measurement and standard condition.

- Separate Terminal block Inputs for pulses, pressure and temperature can be sealed separately from the rest. The lithium battery can be exchanged without opening the case.

INSTALLATION OPTIONS, ARCHIVES, SOFTWARE

Options for Installing the Totalizer

With the TME 400-VM the meter head can be mounted standing or lying as well as rotated about the vertical axis. For TME 400-VC the meter head is mounted standing in any case due to the pulse piping required. For both the TME 400-VM and the TME 400-VC the remote totalizer option for a separated mounting of the meter head in a distance of max. 10 m from the meter body is available.

Archives

Parameter changes, meter readings and events are stored in the archives and for the TME 400-VC additionally measured values. The memory depth is in each case: • Parameter archive (custody transfer) 300 • Parameter archive (secondary) 300 • Event archive 200 • Periodic archive 9000 • Daily archive 100 • Monthly archive 25 The measuring period can be set to 15, 30 or 60 minutes.

Operating software RMGView

TME The provided RMGViewTME software allows direct access to the measuring electronics with a PC. The most important functions are:

Method of Operation

With turbine gas meters, the gas flow strikes a mechani- cally mounted turbine wheel and drives it. The rotational speed of the turbine wheel is proportional to the flow rate of the gas. Since the gas flows through an invariable cross section (annular gap of the turbine wheel), the flow velocity is also proportional to the volume flow.

TME 400 VM and TME VC are based on the on the trusted RMG Volumeter series TRZ03-K. Dimensions and metro- logical performance are identical for both.

In the TME 400, a magnetic disk is mounted on the shaft of the turbine wheel, rotating at the same speed as the tur- bine wheel. A Wiegand sensor scans that disk and generates one electrical pulse per revolution which is transmitted to the electronic meter head. Each pulse is directly proportional to a certain volume flow. The meter can therefore display both the current flow (QM) and the total flowed volume (VM).

Furthermore, the volume corrector integrated in the TME 400-VC allows the calculation of the standard volume (VB). In order to do this, the meter measures operating pressure and operating temperature in addition to the operating volume flow. From this, the standard volume flow can be calculated using a suitable equation of state together with the corresponding standard conditions. Then this value is summed up in the standard volume totalizer and stored in the data logger.