MODEL"DC" Dual Chamber Orifice Fitting

The Canalta Dual Chamber Orifice Fitting is designed and constructed to allow for the orifice plate replacement or inspection under pressure without the interruption of the flow in the line.

The Canalta DC Orifice Fitting is a high quality, high accuracy orifice fitting manufactured in a wide selection of sizes and materials. These units are built to meet or exceed ASME and ANSI specifications as well as to comply with the requirements of the latest editions of AGA-3, ISO-5167and API-14.3. The fittings are available to meet the NACE MR-0175 specification. Stainless Steel internals are also available to meet extreme corrosive applications.

FUNCTIONING AND STRUCTURE

1. Type “K” Standard 2000 Edition Seal Assembly

This is the standard seal assembly supplied with all orifice fittings from sizes 2” through 8”. This unit is used with a 0.562” seal gap for fitting sizes 2” thru 6” and with a 0.688” seal gap for 8” fittings. The single downstream seal function offers superior sealing capability while reducing seal damage during insertion. Plate Seal bypass tested down to 1” water column. It is comprised of an elastomer seal and one stainless steel retainer ring. Exacting and repeatable concentricity is maintained with the metal-to-metal contact throughout the entire circumference of the orifice plate to the plate carrier mechanism.

2. Dual Ring Orifice Plate Seal Assembly

Canalta Dual Ring Orifice Place Seal Assembly offers you (The Customer) an alternative sealing device for those specific or unorthodox situations. This assembly is primarily used to upgrade the .688” seal gap (1985 Edition) orifice fitting bodies to comply with the latest editions of AGA-3 and ISO-5167 but is also available for 0.562” gap fittings (2000 Edition) per customer request. The seal assembly simply mounts into place in the existing plate carrier. It is comprised of a stainless steel plate holder, retainer ring and standard sized O-Ring seals which are available in a variety of compositions. A positive seal is established with the orifice plate and the seal surfaces of the orifice fitting body utilizing the “inner and outer O-Ring” design. Plate seal bypass tested down to 1” water column. When ordering the Dual Ring Orifice Plate Seal Assembly please specify 0.688” seal gap (1985 Edition) or 0.562” plate seal gap (1991 / 2000 Edition).

3. Teflon Snap Seal

The Teflon Snap Seal Provides Positive Plate Sealing in the harshest of process environments. The two piece design snaps over the orifice plate without the use of metal clips or retainers. A specially designed recess absorbs the insertion pressures minimizing permanent compression and distortion. The raised section adjacent to the recess creates a positive seal against the orifice plate preventing bypass leakage. These two unique design features enhance seal performance while extending the life expectancy of the seal assembly.

Soft Seat Details

This unique soft seat design is available at no extra charge. It enables a maintenance free bubble tight seal between upper and lower chambers. Standard size O-Ring seals are incorporated and available in a wide variety of compositions.

Installation Instructions

Orifice Fitting Installation Procedure The Orifice Fitting is normally installed in conjunction with upstream and downstream meter run sections. To meet the recommendations of both A.G.A. Report 3 and ISO 5167, this is essential. To obtain the best measurement results, follow the recommended piping configurations and installation requirements of either of these two standards as well as the below recommendations. The meter run is normally constructed and inspected by the manufacturer of the orifice fitting but there are many reputable meter run fabrication facilities located worldwide.

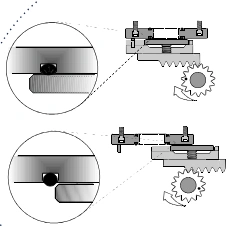

- Attention to clearances is essential. See the attached dimensional drawings for details. Insure there is operating clearance on the sides of the fitting to rotate the inner valve and orifice plate carrier shafts. Insure there is clearance above the top of the fitting for removal of the plate carrier.

- The unit can be installed either in a vertical or horizontal position. When mounting horizontally, the top housing should be located in the upper position for ease of operation as well as to avoid liquid and debris from accumulating in the upper chamber.

- When used to measure wet gas, it is recommended to mount the orifice fitting vertically so as not to form a dam against the orifice plate.

- Instrument tap lines should be installed sloping upward to the differential pressure measurement instrument. Where this cannot be accomplished, use seal pots to chemically seal the sensing lines in order to eliminate hydrostatic head errors.

- Insure that the flow arrow corresponds with the direction of flow in the line.

- After the orifice fitting has been piped in, install the bleeder valve, grease gun and indicator plate on the valve-operating shaft.

- With the two drive screws provided, install the valve position pointer. Insure that the position on the valve indicator plate corresponds with the position of the inner valve.

- It is recommended that the bleeder valve vent be piped away to a safe venting area.

- To avoid damage to the orifice plate, insure the orifice plate and plate carrier are removed from the fitting during pressure testing of the system.

- Before reinserting the orifice plate and plate carrier, insure that no debris has accumulated in the lower cavity of the fitting. If so, remove the lower drain plugs and rod-clean the lower section.

- The orifice fittings equipped with the grease style inner valves were lubricated at the factory prior to shipment. If the unit has been sitting out of service for more than six months, it is recommended that the unit be lubricated prior to being put into service. Refer to the “Lubrication Procedure”.

- To avoid over range damage to the differential measurement instruments and orifice plate during initial pressurization, insure the orifice plate is rolled up out of the flow stream and that the instrument manifold equalization valves are open. 13. Always insure that operation staff are properly trained and are competent to operate this and all other pressurized equipment.

The Single and Dual Chamber Canalta Orifice Information

The Canalta orifice product has two different types that you can purchase right now. Those are the single and dual-chamber versions where two of them have different characteristics.

That is why; it is essential to know all of them so that you can buy based on your own needs. For your information, this item is made by a Canadian company that has created many high-quality products as well.

What is this Canalta Orifice?

This Canalta orifice is a pressure product that is great for many industries in the market. Below are their product applications that you may need to note:

1. Flow Measurement

The company knows that the market needs flexibility when we are talking about pressure products in the market. That is why; Canalta has so many line-ups ranging from tubes, meters, accessories, and parts.

It means that the company can fulfill your needs whether it is related to budget, sour high-pressure fluids, pressure recovery, and so on. The right distributor will help you to get the best products.

2. Differential Pressure Items

There are also many high-quality and affordable flow measurement equipment. This is recommended for any private sector, enterprises, ranging from oil and gas up to the f&b industry.

Types of Canalta Orifice Fittings

This Canalta orifice comes in two different types that you should understand. Below is the complete explanation and details about those types:

1. Single Chamber

This single chamber is specially made and constructed to let you get an easy replacement. Especially for the orifice plate and it is also good for inspection after a moment called depressurization.

There are some characteristics that you can note from this single chamber:

- The whole fittings are standard and they have a package of documentation. This documentation includes the inner valve, hydro-test, material test report, to quality control inspection.

- The ISO–9001 quality control program is applied here, especially for the traceability need.

- The base guidelines for fitting here are ASME 16.34 and also the 16.5 version

You may get additional information from the seller or distributor. That is why; feel free to ask everything that you want to know about this Canalta orifice fitting.

2. Dual Chamber

A dual chamber is highly recommended if you are looking for a great flow measurement. That measurement is so accurate and it also consists of the plate inspection.

You can even change its components without breaking all parts and don’t need to depressurize its flow line. Here is the further characteristic of this dual chamber:

- Just like the single chamber, the dual chamber also has a documentation package.

- All standards are also similar to the single chamber.

Due to its function, this Canalta orifice products can be used by many industries nowadays. Those can be the offshore production platform, sub-sea business, hub terminal, gas pipelines, bulk test separation, and many more.

All Products that You Can Purchase

Canalta, in fact, sells so many items that are distributed through many distributors as well. those products are plates, plate seals, flange unions, single chambers, double chambers, etc.

Buying from the right Canalta orifice distributor will let you get the complete items based on your needs. Besides that, the quality is also guaranteed since all of those items are checked before.

Migasindo is a trusted distributor that can send the items worldwide. You just need to check through our website to know the details and place an order.

We also offer a free discussion service to help you find the right product based on your needs. The great thing is that all items are sold at an affordable price, so it is suitable for household or company use.

Please check our site and order now to get the best offer from us. MIGASINDO is the best place to purchase many Canalta orifice products that are original and supported by great technology.