The Turbine Meter TRZ 03

METHOD OF OPERATION, CONSTRUCTION

A. Method of operation

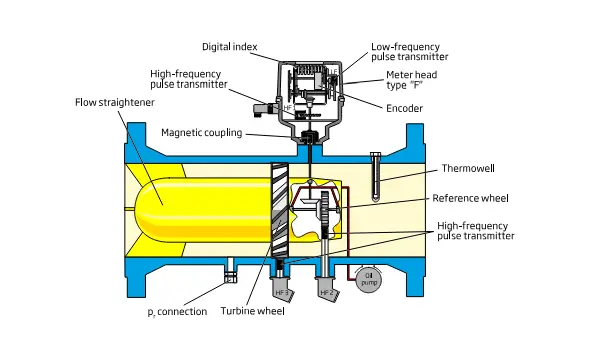

The TRZ 03 turbine meter is a flow meter suitable for gasmeasurement in compliance with EN 12261 and OIML,where the rate of flow is indicated by a mechanical totalizer in units of volume (cubic meters at flowing conditions)under prevailing pressure and temperature.The gas flow is constricted to a definite cross section anddrives a coaxially mounted turbine wheel. The speed ofthe turbine wheel, which is proportional to the flow rate,is reduced by gearing and transmitted to the mechanicaldigital index.

B. Construction

The meter case comprises the measuring element with theturbine wheel. A flow straightener located upstream ofthe measuring element substantially eliminates turbulences and swirl from the gas flow and directs the gas ontothe turbine blades.The rotary motion generated by the turbine wheel istransmitted by a magnetic coupling from the pressurizedmeter case to the unpressurized meter head.The number of rotations is reduced by gearing in the meterhead, which can be adjusted by selecting an appropriatepair of adjusting gears, so that cubic meters at flowingconditions are indicated by the mechanical totalizer. A reedcontact (or an inductive sensor) located on the mechanicaltotalizer provides low-frequency pulses whose numberis proportional to the volume at actual conditions flowedthrough.Inductive high-frequency sensors scan the turbine wheel(HF 3) and the reference wheel (HF 2). The latter is a camwheel located on the same shaft as the turbine wheelwhich enables the turbine wheel to be monitored.Furthermore, the meter head can be equipped with an encoder for digital transmission of the totalizer reading (Vo)to a volume corrector.

FEATURES, MATERIALS

Features

LF-Pulse transmitter (in the meter head)

Standard: reed contact

Alternatively : inductive pulse transmitter

Option: up to 3 LF pulse transmitters possible

HF-pulse transmitter (option)

- In the meter head:

Inductive pulse transmitter (HF 1), pulse frequency at

Qmax approx. 100 Hz. - In the meter case:

Inductive pulse transmitter for scanning

– the blades of the turbine wheel

(HF 3, from DN 80)

– the cams of the reference wheel

(HF 2, from DN 100) - All inductive pulse transmitters provide volume pulses

in compliance with NAMUR.

Meter head (type “F”)

Protection class IP 65

• Universally readable

• Totalizer unit and HF1 pulse transmitter are easily

replaceable on site. - built in encoder of type ENCO 08 (option);

no battery required.

Thermowell(s) inside the meter case (option)

To accommodate a resistance thermometer each.

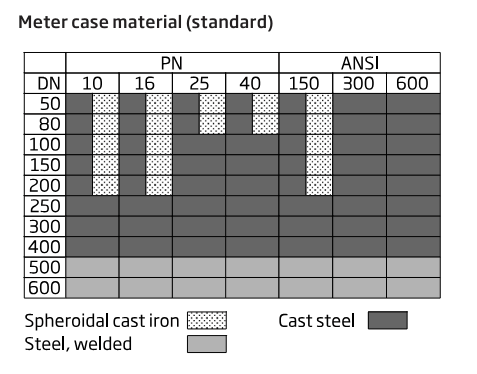

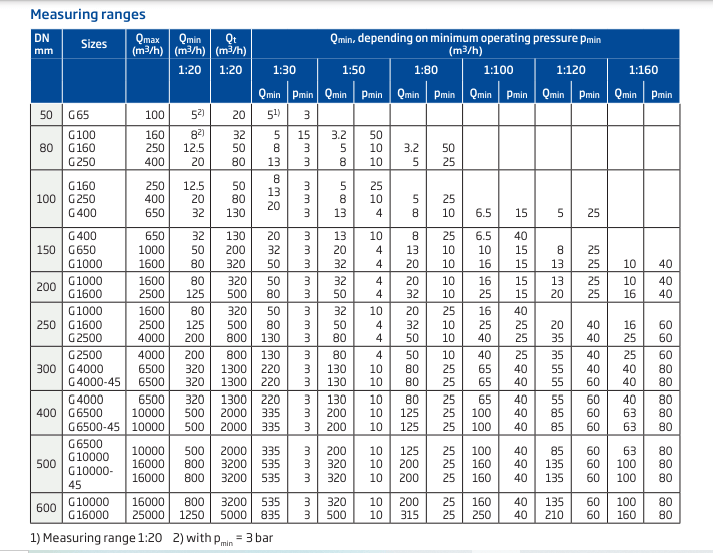

Standard measuring range 1:20 (MID) With high-pressure testing, measuring ranges up to 1:160 are possible (depending on operating pressure). Nominal size: DN 50 through DN 600 Pressure rating: PN 10 through PN 100, ANSI 150 through ANSI 600 Operating temperature ranges: acc. to MID: -25°C to +55°C acc. to PED: -20°C to +80°C (spheroidal cast iron) -40°C to +80°C (cast steel) acc. to ATEX: -25°C to +70°C Explosion protection The pulse transmitters are intrinsically safe; their type of protection is Ex ib IIC T6. Therefore, the TRZ 03 can be operated in Zone 1. Long service life pr -connection To connect the pressure transmitter of a PTZ corrector. Inspection report In compliance with EN 10204/3.1, for strength and leak testing.

Materials

Rotor: Delrin for DN 50 to DN 200 and PN 10 / PN 16.Aluminium alloy for all other diameters and pressure ratings and for meters with HF sensors.Aluminium rotors instead of delrin rotors on special request

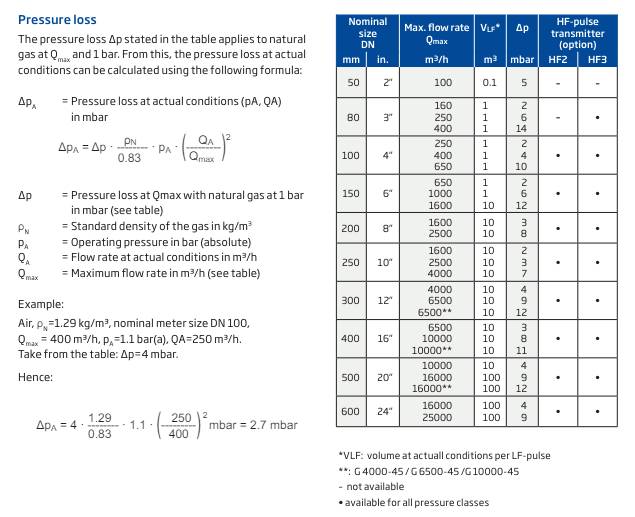

ACCURACY, APPROVAL, PRESSURE LOSS

Accuracy

Error limits (standard):

±1.0% for Qmin to 0.2 Qmax±0.5% for 0.2 Qmax to QmaxThese limits (half calibration error limits) apply in the eventof a steady, swirl-free flow for an operating pressureabove 4 bar and measuring range 1:20. Below 4 bar, thecalibration error limit is reached.Higher accuracy available on special request.Repeatability: ±0.1%All gas meters are tested in the factory with air underatmospheric pressure.

Approvals

The TRZ 03 turbine meter has been approved for custodytransfer flow measurement.The reference number for approval is as follows:MID approval: T10417

The TRZ 03 is also approved for high pressure applicationswith pressure ratings up to ANSI 600:PED approval: CE0091

TYPES OF GAS, MOUNTING AND OPERATING INSTRUCTION, MAINTENANCE

Types of gas

The TRZ 03 standard design is suitable for use with allgases in compliance with the DVGW code of practice G260.The materials used are appropriate for gases and fuelgases, such as natural gas, refinery gas, gaseous liquidgases and their mixtures, nitrogen, CO2 (dry), air and allinert gases.For aggressive gases (e.g. biogas, acid gas or ethylene),there are special designs available with PTFE lining, specialmaterial, special lubrication, etc

Mounting and operating instruction

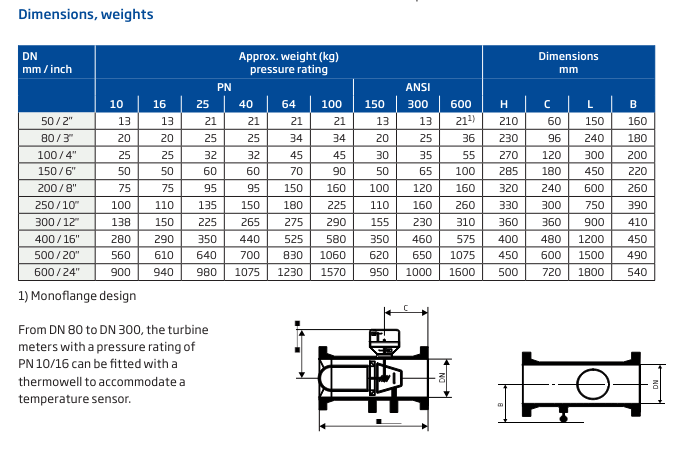

The TRZ 03 turbine meters can be operated in horizontalor vertical position up to the nominal size of DN 150. For DN200 the mounting position must be specified in the order.

From the nominal size of DN 250, they can only be installedin a horizontal position.Special instructions for startup and operation:Turbine meters are precise measuring instruments andmust therefore be carefully handled during transport,storage and operation.Do not fill any downstream pipelines or station sections viathe turbine meter. This may result in excessive flow rateswith resultant damage to the turbine wheel.

The gas meter has been designed for short-term overloadoperation at up to 1.2 times the value of Qmax. Such loadconditions should be avoided, however, in order to protectthe TRZ 03 from any unnecessarily high flow rates.The gas flow must be free of shocks or pulsations, foreignparticles, dust or liquids.

Otherwise it is recommendedthat filters and separators be installed.No components affecting the gas flow are permitteddirectly upstream of the turbine meter (see DVGW guidelines and PTB guideline G 13)

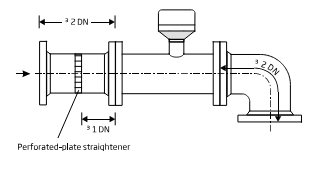

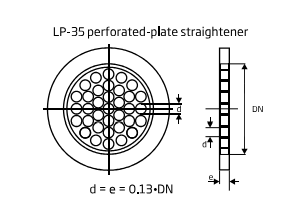

In each case, an inlet pipe is required whose length asspecified in the type approval may be shorter than thatspecified in the Technical Guideline G 13. The lengths ofthe inlet and outlet pipes must be at least 2 DN, whilealso a bend may be used as outlet pipe. If there is a heavyflow perturbation (e.g. due to a gas pressure controller)upstream of the inlet pipe, it is additionally necessary touse a perforated-plate straightener. There are perforated-plate straighteners available of the type RMG LP-35,the latter resulting in a pressure loss which is 2.5 timeslower than that of a standardized flow straightener complying with ISO 5167.

Maintenance

All turbine meters are fitted with a lubricator (DN 50through DN 150: permanent lubrication, from PN 25/ANSI 300 pushbutton pump; DN 200: pushbutton pump;from DN 250: lever pump).Lubrication must be performed in compliance with theoperating instructions (see also the lubrication instructionplate of the gas meter).

If clean gas is used, lubrication isto be performed at 3-month intervals, whereas lubricationmust be performed more frequently if dust- and/or condensate-laden gas is used.

PULSE OUTPUTS, DIMENSIONS, WEIGHTS

Pulse outputs

The meter head is fitted with a reed contact as LFpulse transmitter as standard feature. But optionally,another two sensors can be fitted, e.g. another LFpulse transmitter (inductive sensor with output pulsescomplying with NAMUR or reed contact) and an HF1 pulsetransmitter (NAMUR).

Connection is made by means of a 7-pin Binder plug:

If only one LF pulse transmitter is fitted, it is alwaysconnected to the contacts 1 and 4; a single HF1 pulsetransmitter is always connected to the contacts 3 and 6.

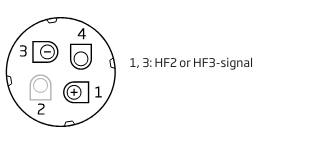

If high-frequency pulse transmitters (with output pulsescomplying with NAMUR) are fitted which scan either theturbine wheel (HF3) or the reference wheel (HF2), eachof them is connected separately using a Binder plug at thefront of the device:

The contacts 2 and 4 are not assigned.All pulse transmitters are intrinsically safe and may beconnected only to certified intrinsically safe circuits foruse in areas subject to explosion hazards.Maximum pulse transmitter frequencies:LF: 0.3 Hz HF1: 300 HzHF2: 2.1 kHz HF3: 2.1 kHzThe phase displacement between the signals from the HF2and HF3 pulse transmitters is 180°.

MEASURING RANGES, ORDER INFORMATION

What is RMG Turbine flow Meter and Why You Need It?

RMG Turbine flow meter is one of the most popular oil and gas equipment that is looked at by people. The reasons are varied from its strong performance, affordable price, and so on.

Whatever it is, you need to understand more about this tool first. That is why; here we will give a short explanation about this equipment and why you need it.

What is a Turbine Flow Meter?

This tool is commonly known as a gas meter as well. Many experts will recommend you use this option to measure gas. That is why; it is mostly used by industrial companies or even a household use.

You will see that the flow in this RMG Turbine flow meter is shown by a mechanical counter. It uses the volume unit (meter cubic) in a used pressure and temperature.

The gas flow is limited in certain cross-sections and it will move the turbine wheels which are coaxially installed. The turbine wheels which are in line with the flow will be reduced by using a gearing.

The meter head gearing can be set by choosing a pair of smaller wheels there. Just set them based on your need, so that it will create a better meter cubic.

You may see that the head meter can be equipped with an encoder. The encoder here is important for a digital transmission of reading (Vo) to a volume corrector.

Materials and Features

Besides knowing the general information above, it is also recommended to reveal its features. This RMG Turbine flow meter has some important features to support its performance as follows:

- LF – Pulse Transmitter that is placed in the meter head

- Reed contact as its standard

- The inductive pulse transmitter can be used as an alternative

- The option is up to 3 LF pulse transmitter

- Another possible option is the HF Pulse Transmitter

- In the meter head, you can see some parts such as the HF 1, pulse frequency, and many more.

We can say that there are some types of RMG Turbine flow meter that are sold in the market right now. Each of them may come with different features such as protection from an explosion, alarm output, and so on.

Commonly, this tool is supported by a long-lasting battery to do its operation. In conclusion, every part has been considered well to give maximum function and safety.

How it is Worked?

The working process of this RMG Turbine flow meter is actually not hard. During measurement, this gas molecule usually walks through the gauge continuously where it creates some beats during calibration.

Sound dampening is an additional material if you want to reduce significant measurement errors. Furthermore, turbine meters have some different components to support their function.

Those components are gear systems, then turbine wheels, extrusion parts, and closed housing units. When the gas flows, the turbine wheel will begin to rotate as soon as possible.

This rotation is proportional or in line with the flow speed. Therefore, the gas volume can be calculated due to the rotation of this wheel. That is a simple work process of this equipment that you can note.

The Best RMG Turbine Flow Meter Distributor

Migasindo is a trusted distributor to complete your oil and gas equipment. You can take a look at our website to know all the products and their details.

The items we sell can be delivered or shipped to all over the world. We will ensure you get the original and best products so that you can have a long-lasting life.

So, call us right now to purchase your oil and gas equipment and we can help you to find the right item too. One of them is the RMG turbine flow meter which is sold at an affordable price.

Turbin RMG TRZ03 Compact Design and the Features

If you run an oil and gas (or other similar sectors) industry, the turbin RMG TRZ03 is maybe a popular equipment in the market. It is known as one of the best options that you can have.

There are some reasons why this item is highly recommended. One of them is its compact design that is equipped with some great features. You must check out everything, so this tool can be used properly.

The Compact Design Advantages

The compact design that this turbin RMG TRZ03 may make it has a bit higher price than others. However, it is in line with the quality because this tool is more sensitive, especially for the fluid dynamic aspect.

On the other side, the high reproducibility from a measured value is a feature that is owned by Volumeter with a turbine meter. That is why; volumeters are used to measure the internal billing or factory control.

An example is the burner control system. The reproducibility of value that is measured here is crucial for a control aim and regulation process. This equipment is good for measuring how much the gas quantity is.

It is especially in industrial sectors which don’t need to be calibrated. Furthermore, this TRZ03 is also reliable and cost-effective. You will get high measurement accuracy by using this equipment.

The Features that It Has

This turbin RMG TRZ03 is completed with a mechanical output clutch that has been tested by DIN-DVGW. This device is also a good measure of the gas volume that has non-custodial traffic.

Furthermore, this TRZ03 is suitable for any gasses that are based on the DVGW worksheet G 260. It is great for neutral, non-aggressive, and other gasses that you request.

Another feature here is a roller counter that can register the whole volume. Besides that, it can display the result of volume at any time, even if you don’t use a power supply.

This turbin RMG TRZ03 also has vertical and horizontal gas flow. Optionally, it comes with a mechanical output clutch and the compact design can handle aggressive gases properly.

Installation and Points to Note

The installation processes have been listed clearly in its manual book. It is essential to read that guide, so that you can install this equipment properly. You may ask a help from professional about this installation need.

One thing for sure is you need to pay attention to the direction of flow. This flow direction is indicated by the arrow symbol where you can follow that symbol to install this tool properly.

This thing is a measuring instrument. That is why; all processes must be handled carefully from the delivery process, storage, and operation, up to installation.

To make this tool have a long-life performance, please ensure that there is not any liquid in the gas line. It is especially after the hydrostatic test because this problem can damage the interior part.

The Turbin RMG TRZ03 Distributor

You must note that this turbin RMG TRZ03 has several versions such as the common 03, TRZ O3 E, type K, and L. Each of them is quite similar, but usually, there are a bit differences that you can note.

Migasindo is a trusted distributor where you can buy this equipment. All of the products are originals, and they perform well. All of your order will be shipped or delivered wherever you are.

Please visit our official website to learn about this item or other products that we sell. You can also place an order from our website, and we will respond quickly.

So, contact us right now. You can discuss your needs with us to get the best product. We will ensure that our clients get the best turbin RMG TRZ03 or other equipment in every order.