ULTRASONIC FLOWMETER USM GT400

The ultrasonic meter USM GT400 from RMG delivers highest accuracy and reliability based on fi eld proven six path technology.

WHY GT400 BY RMG ?

The ultrasonic meter USM GT400 from RMG delivers highest accuracy and reliability based on fi eld proven six path technology. Designed for use in a wide range of gas custody transfer and secondary metering applications, the GT400 measures directly bulk fl ow rate, swirls, cross-fl ow and asymmetry. Its patented live precision adjustment/ echo measurement reduces metering uncertainty.

Proven Technology. Superior Performance. To remain competitive, today’s natural gas industry is under pressure to reduce capital and operating costs, improve uptime and reduce risk. Reduction of workforce, more automation and aging workforce, with nearly half of employees skilled in control and regulatory technologies are expected to retire over the next years.

Often, end users must cope with challenges such as high gas pressure or temperature, valve noise, and attenuation of signal due to contamination or the presence of liquids. This requires intelligent solutions to maintain accuracy while transferring gas between the distributor and the recipient.

ACCURACY ENSURED

The USM GT400 ultrasonic fl owmeter from RMG provides high accuracy, reliability and long-term stability in the most demanding environments.

Proven Technology

Today, intelligent solutions are needed to measure and analyze the quality and volume of natural gas at every stage of its movement, storage and utilization. Gas industry organizations can meet this requirement with RMG’s Regulating and Metering product lines, which are available individually or as complete systems for gas metering stations. RMG has more than 150 years of experience, supplying solutions to the major gas transmission companies in Europe and Asia.

Application Know-how

We partner closely with industrial, commercial and gas distribution customers to provide the right fl ow measurement solution to optimize operations at gas-fi red power plants, liquefi ed natural gas (LNG) storage and export terminals, city gate facilities, petroleum refi neries, metals and mineral processing plants, combined heat and power generation facilities, and all sites utilizing natural gas as a feedstock.

Expert Support

Our gas industry experts assist with developing standard operating procedures (SOPs) for gas metering station installations, validation routines, calibration procedures, and more. Integrated ultrasonic gas meters with control or SCADA platforms and data collection systems help you interpret meter diagnostics and troubleshoot operating problems.

Local Service

You can depend on RMG for long-term product reliability and performance, lowest total cost of ownership and installation. Global experience, locally applied.

Konsultasikan Kebutuhan Anda Kepada Kami

Dapatkan Harga dan Kualitas Terbaik

FEATURES AND FUNCTIONS

For natural gas processes with dry, wet, or corrosive and abrasive gases, or requiring bi-directional measurement with minimal or no pressure drop, ultrasonic devices generally off er better performance, greater reliability, and lower capital and ownership costs than mechanical metering technologies.

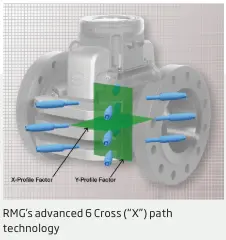

Proven Six-path Technology

The GT400 is designed with high stability against turbulence thanks to its direct path technology with six measuring paths on three levels. The paths are arrayed in an “X” pattern in horizontal planes: a central plane, and two geometrically similar planes.

This orientation permits measurement of swirl, cross-fl ow and asymmetry, as well as transparent path velocity weighting per the Gauss-Chebyshev profi le model for compressible fl uids. It is particularly benefi cial in city gate applications, where limited space for piping and installation can aff ect meter operation.

Field-proven Electronics

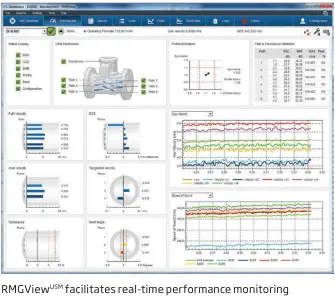

The GT400 incorporates electronics that have improved metering system uptime in installations worldwide. The electronics are used to optimize the meter’s internal diagnostics; speed of sound (SoS and fl ow velocity calculations; signal processing; data storage; interface to fl ow computers, gas chromatographs and SCADA systems; and fi eld service diagnostics tools.

Plug & Play Transducer Design

At the heart of the GT400 are its transducers, which transmit and receive sound waves or acoustic pulses. The transit time diff erence between pairs of transducers is the most signifi cant aspect of meter operation.With the GT400, all path-specifi c measurements are handled internally by the electronics. RMG’s Exd transducer consists of piezoelectric crystals fully encapsulated in Titanium housing for resistance to contamination.

This unique design is plug & play and fi eld-replaceable under pressure. The transducer operates at standard frequencies of 120 or 200 kHz for use in most gas metering applications. Temperature range is -40°C to +80°C (-40°F to +176°F) and pressure range is 1 bar to 300 bar (14,5 psi to 4351 psi). Wide measuring ranges (120:1 and above) with correspondingly high fl ow velocities of more than 40 m/s (131 ft/s) are also possible.

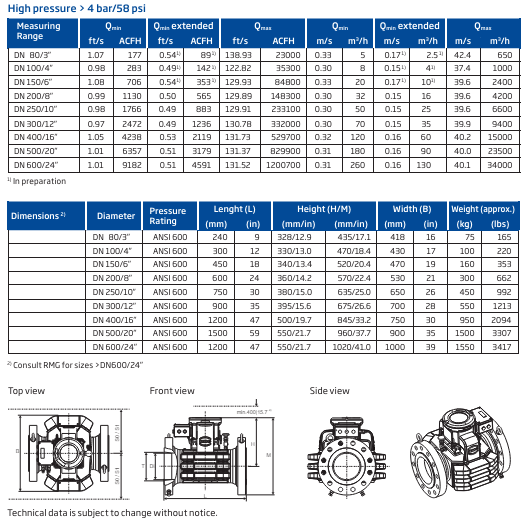

TECHNICAL SPECIFICATION

Ultrasonic Flowmeter USM GT400 Equipment and Its Advantage

One of the equipment sold by many distributors is the ultrasonic flowmeter USM GT400. It has become one of the most recommended item to use, especially for the gas industry.

All of us know that the natural gas industry is now quite competitive. It needs the right material to support the business where the capital and operating costs should be reduced wisely.

The Best Solution for the Gas Industry

The business owners and employees right now need to face some challenges. Those are the valve noise, high gas pressure, high temperature, up to the attenuation of the signal.

That can be caused by the contamination or the existence of certain liquids. That is why; you must find the right solutions related to accuracy. This is especially true when the gas is transferred between the recipient and distributor.

This ultrasonic flowmeter USM GT400 has many advantages for this industry. Made by Honeywell, this tool will give the highest reliability and accuracy due to the field-proven 6 technologies.

You can use this equipment in various ranges of gas custody transfers. It is also good for secondary metering use. This GT400 can measure the bulk flow rate straightly, cross-flow, swirls, and asymmetry as well.

Why You Have to Choose the USM GT400

There are some reasons why this ultrasonic flowmeter USM GT400 is highly recommended. It has a wide range of benefits to support your business as follows:

- Advanced noise immunity where this tool can work in a calmer sound.

- Excellent Diagnostic technique. It uses Windows-based and RMG view parameterization. The diagnostic software is also applied here to do a better condition monitoring capability.

- User interface that is really intuitive. It can be connected via a PC as an electronic measuring system. There you can read all parameters, change them, and other needed actions.

- Delay time adjustment that is more precise.

The Benefits of Ultrasonic Flowmeter USM GT400 for a Business

Since it has a lot of good features, this tool is recommended for your business. Here is why you should try to use this ultrasonic flowmeter USM GT400 to support your business:

1. Lower CAPEX

This equipment lets you reduce the budget for using a newer and more advanced gas metering system. This is because this component can employ smaller size meters that have a greater rangeability.

Besides that, the flow velocity is also higher and has an extended turndown as well. For your information, this GT400 also has a crossed-path arrangement that can trigger high-accuracy measurements.

2. Improved Uptime

This flowmeter comes with a technology that can stay away from any unplanned losses and shutdowns. It also has redundancy with two paths to give you greater reliability even in an extreme condition.

A titanium sensor surface is attached to this ultrasonic flowmeter USM GT400 and it is contaminant-repellant. That is why; you don’t need to shut down any processes when cleaning time needs to be done.

You will also love the plug-and-play design that is designed. The reason is this feature will shorten the duration needed for exchanging sensors.

3. Reduced Risk

To ensure you get the best service and performance from this tool, the technicians will help with field service. It also comes with start-up commissioning assistance.

Migasindo is the right place where you want to get the best oil and gas equipment like this USM GT400. There are so many products that you can purchase and all of them are in the best condition.

Please come and visit our website to explore more about the details. You can also purchase other equipment related to oil and gas for your company or household use.

So, contact us right now to do all the process right away and our staff will help you too. The ultrasonic flowmeter USM GT400 can be delivered worldwide in a safe way.